Tsanangudzo

SILIKE Si-TPV 2250 Series imhando ye elastomer yakagadzirwa ne thermoplastic silicone yakagadzirwa kuti iwedzere EVA foaming materials. Si-TPV 2250 Series inogadzirwa uchishandisa tekinoroji yakasarudzika inoita kuti silicone rabha iparadzirwe zvakaenzana muEVA se 1–3 micron particles. Iyi modifier yakasarudzika yezvinhu zvinogadzira furo zveEVA inosanganisa simba, kuomarara, uye kuramba kukwesha kwe thermoplastic elastomers nehunhu hunodiwa hwe silicone, kusanganisira kupfava, kunzwa kwe silky, kuramba UV, uye kuramba makemikari. Inogona kudzokororwa uye kushandiswazve mumaitiro echinyakare ekugadzira.

Zvinhu zveSi-TPV 2250 Series Eco-Friendly Soft Touch Material zvinoenderana zvakanyanya ne ethylene-vinyl acetate (EVA) uye zvinoshanda se silicone modifier itsva yeEVA Foaming, Mhinduro dzekuvandudza zvinhu zveEVA foam muzvishandiso zvakaita sezvigadziko zveshangu, zvigadzirwa zvehutsanana, zvigadzirwa zvemitambo, mat floor mats, mat yoga mats, nezvimwewo.

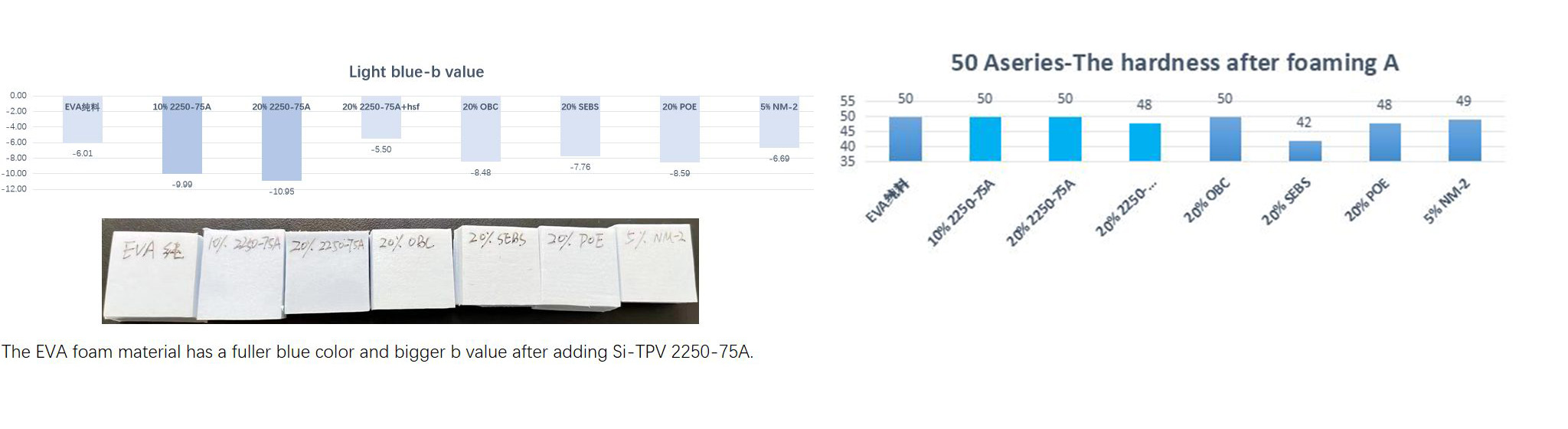

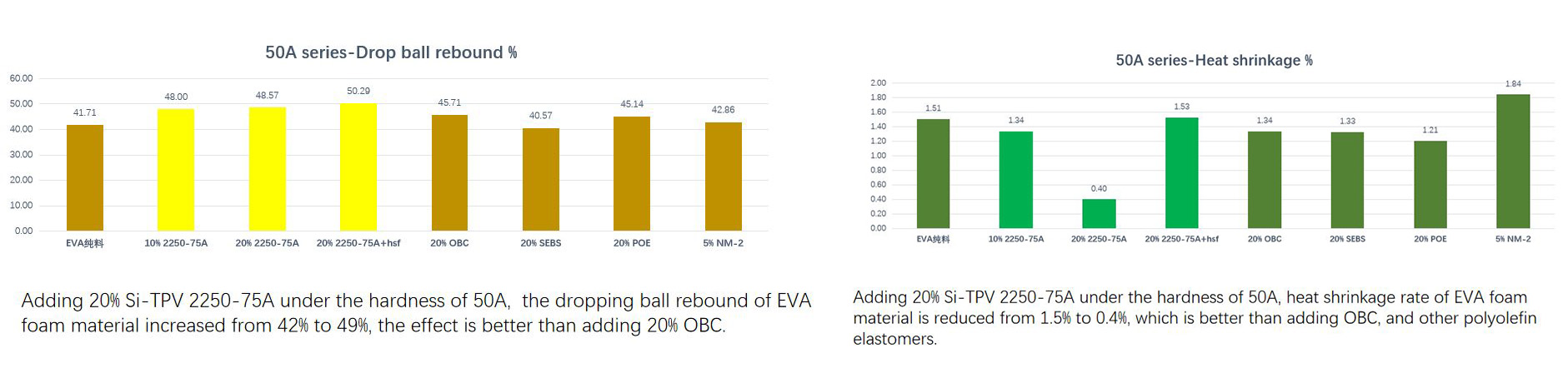

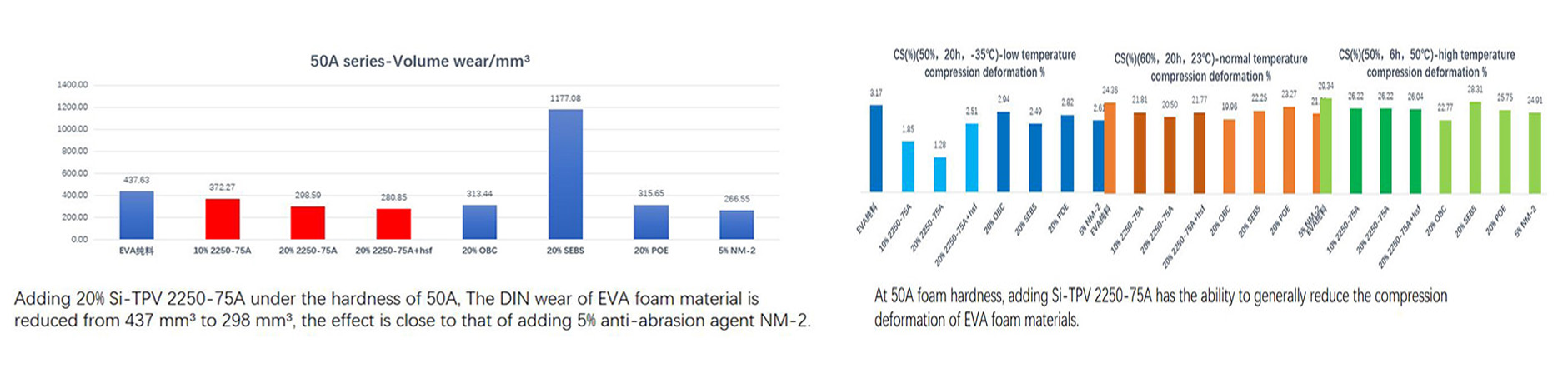

Zvichienzaniswa neOBC nePOE, Highlight inoderedza kudzvanywa uye mwero wekupwanyika kwemafuta eEVA, inovandudza kusimba uye kupfava kweEVA furo, inovandudza kudzivirira kutsvedza uye kurwisa abrasion, uye kupera kweDIN kunoderedzwa kubva pa580 mm3 kusvika 179 mm3 uye inovandudza kuzara kwemavara emafuta eEVA furo.

Izvo zvakaratidza kushanda zvakanaka kweFlexible Soft Eva Foam Material Solutions.

Mabhenefiti Akakosha

Kugara kwenguva refu Kugara kwenguva refu

- Tekinoroji yepamusoro isina zvinonyungudutsa, isina plasticizer, isina mafuta anonyorovesa, uye isina hwema.

- Kudzivirirwa kwezvakatipoteredza uye kugona kudzokororwa.

- Inowanikwa mumafomura anotevedzera mitemo.

Si-TPV Modifier yeEVA Foaming Case studies

Si-TPV 2250 Series ine ganda rakapfava kwenguva refu, inodzivirira mavara zvakanaka, uye haidi kuwedzerwa mapurasitiki kana zvinonyorovesa. Inodzivirirawo kunaya kwemvura mushure mekushandisa kwenguva yakareba. Semugadziri wefoam yeEva inopfava inoenderana zvikuru uye ine hunyanzvi, yakanyatsokodzera kugadzirira zvinhu zveEVA zvine furo, zvinopfava uye zvinochengetedza nharaunda.

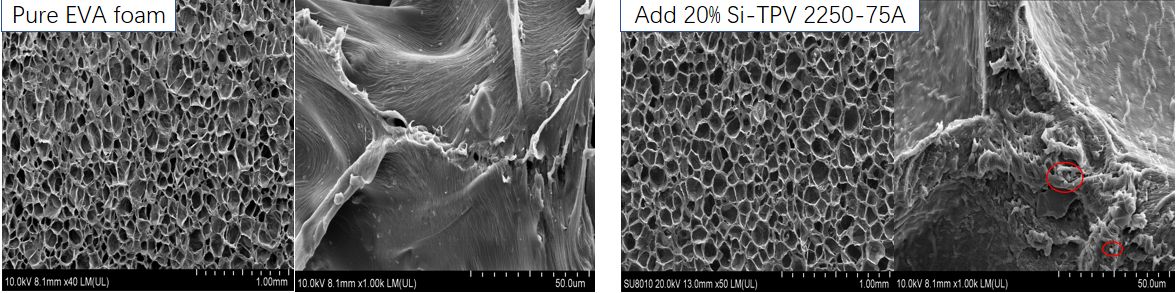

Mushure mekuwedzera Si-TPV 2250-75A, huwandu hwemabubble cell eEVA furo hunodzikira zvishoma, madziro emabubble anokora, uye Si-TPV inopararira mumadziro emabubble, madziro emabubble anova akaomarara.

Kuenzanisa kwaSi-TPV2250-75A uye polyolefin elastomer zvinowedzera muEVA furo

Kushandiswa

Si-TPV modifier itsva yegirini isingatsvedzere nharaunda inopa simba kune zvinhu zvinofema zveEVA zvakagadzirisa zvinhu zvakasiyana-siyana zvehupenyu hwezuva nezuva uye zvebhizinesi. zvakaita seshangu, zvigadzirwa zvehutsanana, mapiro ekugezera, zvigadzirwa zvemitambo, mameti epasi/yoga, matoyi, kurongedza, zvishandiso zvekurapa, zvishandiso zvekudzivirira, zvigadzirwa zvisingatsvedzeri mumvura, uye mapaneru emagetsi ezuva nezuva…

Kana wakanyanya kutarisa pamhinduro dzekushandisa furo risingakoshi, hatizive kana riri rako, asi iyi Si-TPV modifier inochinja tekinoroji yemakemikari yefuro. Kune vanogadzira furo reEVA vanogona kuva imwe nzira yekugadzira zvigadzirwa zvakareruka uye zvinochinjika zvine saizi chaiyo.

Mhinduro:

Kuvandudza Mafoam eEVA: Kugadzirisa Matambudziko eFoam eEVA neSi-TPV Modifiers

1. Nhanganyaya yezvinhu zveEVA Foam

Zvinhu zveEVA furo imhando yefuro rakavharwa rinogadzirwa kubva musanganiswa we ethylene ne vinyl acetate copolymers, ine polyethylene nezvimwe zvinhu zvinofema uye catalysts zvinounzwa panguva yekugadzira. Inozivikanwa nekugona kwayo kuchenesesa, kunyudza shock, uye kudzivirira mvura, furo reEVA rine chimiro chakareruka asi chakasimba chinopa insulation yakanaka yekupisa. Hunhu hwayo hunoshamisa hunoita kuti furo reEVA rive chinhu chinoshanduka-shanduka, chinoshandiswa zvakanyanya muzvigadzirwa zvezuva nezuva uye mashandisirwo akakosha mumaindasitiri akasiyana-siyana, akadai sema soli eshangu, ma soft foam mats, ma yoga blocks, swimming kickboards, floor underlay, nezvimwewo.

2. Ndezvipi Zvinogumira paMafuro eEVA echinyakare?

Vanhu vazhinji vanofunga kuti zvinhu zveEVA furo musanganiswa wakakwana wegoko rakaoma negoko rakapfava, Zvisinei, kushandiswa kwezvinhu zveEVA furo kwakaganhurirwa kusvika pamwero wakati nekuda kwekusasimba kwekukwegura, kusasimba kwekuchinjika, kusachinjika, uye kusasimba kwekukwesha. Kukwira kweETPU mumakore achangopfuura uye kuenzanisa kwemasampuli kunoitawo kuti shangu dzeEVA furo dzive dzakasimba zvishoma, dzinodzoka zvakanyanya, dzinochinja kusimba kwesimba, uye dzimwe hunhu hutsva.

Pamusoro pezvo, Matambudziko Ezvakatipoteredza Nehutano Pakugadzirwa Kwefoam reEVA.

Zvigadzirwa zveEVA zvine furo zvinotengeswa pamusika parizvino zvinogadzirwa nenzira yemakemikari yekubvisa furo uye zvinonyanya kushandiswa pazvigadzirwa zvakaita sezvishandiso zveshangu, mameti epasi, nezvimwe zvakadaro zvinosangana zvakananga nemiviri yevanhu. Zvisinei, furo reEVA rakagadzirwa nenzira iyi uye maitiro acho rine matambudziko akasiyana-siyana ekuchengetedza nharaunda uye hutano, uye kunyanya, zvinhu zvinokuvadza (kunyanya formamide) zvinogara zvichiparadzaniswa kubva mukati mechigadzirwa kwenguva yakareba.