ChiiKuumbwa kweNylon Overmolding?

Kugadzira nylon overmolding, inozivikanwawo se nylon two-shot molding kana kuti insert molding, inzira yekugadzira inoshandiswa kugadzira zvikamu nezvinhu zvakasiyana-siyana. Inowanzo sanganisira kuisa nylon yakanyungudutswa pamusoro pe substrate yakagadzirwa kare, senge purasitiki, simbi, kana chimwe chinhu, kugadzira chinhu chimwe chete, chakabatanidzwa. Maitiro aya anobvumira kusanganiswa kwezvinhu zvakasiyana zvine hunhu hwakasiyana, zvichikonzera zvikamu zvinopa mashandiro akanaka uye mashandiro.

Matambudziko muNylon Overmolding:

1. Matambudziko Ekunamatira: Kuwana kubatana kwakasimba pakati penylon ne substrate zvinhu kunogona kuoma, kunyanya kana substrate ine pamusoro wakatsetseka kana usina maburi, uye kana uchishanda nezvinhu zvakasiyana. Kusabatana zvakanaka kunogona kukonzera kupatsanurwa, kutadza kushanda zvakanaka, uye kusagadzikana kwenguva refu.

2. Kukombama uye Kudzikira: Nylon inowanzoitika pakukombama uye kudzikira panguva yekuumbwa, izvo zvinogona kukonzera kusarongeka kwehukuru uye zvikanganiso zvinogona kuitika muchigadzirwa chekupedzisira. Dambudziko iri rinonyanya kuitika muzvikamu zvikuru kana zvakaoma.

3. Kuenderana Kwezvinhu: Matambudziko ekubatana anogona kuitika kana ukaisa nylon pamusoro pezvimwe zvinhu, zvichikonzera kutadza kubatana, kana kuora kwechinhu uye zvikanganiso pamusoro. Zvakakosha kusarudza zvinhu zvinoenderana uye kurapwa kwepamusoro kuti uve nechokwadi chekuti overmolding inobudirira.

4. Mutengo: Kugadzira pamusoro penylon kunogona kudhura kupfuura maitiro echinyakare ekuumba, kunyanya kana tichifunga nezvemitengo yezvinhu, mari yekushandisa maturusi, uye nguva yekugadzira.

Mhinduro dzekukunda Matambudziko muNylon Overmolding:

1. Kugadzirira Pamusoro: Kugadzirira pamusoro kwakakodzera kwakakosha kuti pave nechokwadi chekuti nayiloni nezvinhu zve substrate zvinonamira zvakasimba. Izvi zvinogona kusanganisira kuchenesa, kupuruzira, kana kukwesha pamusoro pe substrate kuti zvikurudzire kubatana. Matekiniki akadai sekukwesha pamusoro, kukwesha makemikari, kana kurapwa kweplasma zvinogona kuvandudza kubatana pakati penayiloni ne substrate.

2. Kugadzirisa Magadzirirwo Echiumbwa Chemhando Yevhu: Kugadzirisa magadzirirwo echiumbwa chevhu kunogona kubatsira kuderedza matambudziko ekukombama uye kupwanyika kwechinhu chine chekuita nenylon. Zvinhu zvakaita sehukobvu hwemadziro hwakafanana, nzira dzakakwana dzekutonhodza, uye maangle ekudhonza zvinogona kubatsira kudzora kupwanyika uye kuderedza kushushikana kwemukati.

3. Kusarudza Zvinhu: Kusarudza mhando chaiyo yenylon uye substrate kwakakosha pakuona kuti zvinhu zvinoenderana uye kuti zvibudirire. Kuita bvunzo dzezvinhu zvinoenderana uye kusarudza zvinhu zvine coefficients yakafanana yekuwedzera kwekupisa kunogona kuderedza matambudziko angangoitika.

4. Kugadzirisa Maitiro: Kugadzirisa maparamita ekuumba, akadai sekupisa, kumanikidzwa, uye nguva yekutenderera, kunogona kugadzirisa maitiro ekuumba zvakanyanya uye kuvandudza kunaka kwechikamu. Matekiniki epamusoro ekuumba, akadai sekuumba nejekiseni rinobatsirwa negasi, anogonawo kushandiswa kuderedza kukotama nekuderera.

5. Matanho Ekutonga Hunhu: Kushandisa matanho akaomarara ekudzora hunhu panguva yekugadzira kunogona kubatsira kuona nekugadzirisa zvikanganiso pakutanga. Kuongororwa nguva dzose kwezvikamu zvakaumbwa, kuongororwa kwehunhu hwechigadzirwa, uye kuyedzwa kwekushanda kunogona kuve nechokwadi chekuti zvigadzirwa zvekupedzisira zvinosangana nezvinodiwa.

Kuvhura Unyanzvi: Si-TPV Inopa Vagadziri Simba reKubudirira muNylon Overmolding Challenges

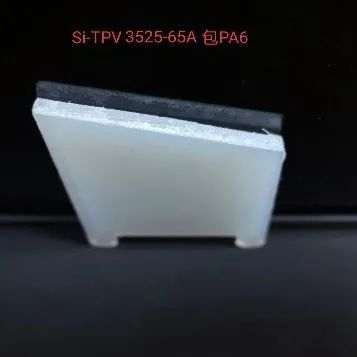

Si-TPV ipurasitiki yepurasitiki inochinja-chinja inosanganisa zvinhu zvakanakisisa zve silicone rabha nema thermoplastic polymers. Iyi purasitiki itsva inopa musanganiswa wakasiyana wekupfava, kuchinjika, uye kugara kwenguva refu, zvichiita kuti ive yakakodzera kushandiswa kwakasiyana-siyana kwe overmolding. Kusiyana nezvinhu zvechinyakare, Si-TPV inoratidza dynamic vulcanization, zvichibvumira hunhu hwepamusoro hwemakanika uye kunamira zvakanaka kune nylon substrates.

Mabhenefiti Akakosha eSi-TPV paNylon Overmolding:

Kupfava Kusingaenzaniswi: Si-TPV inopa kunzwa kwakapfava uye kwakafanana nekutsvedza kuzvikamu zvakaumbwa, zvichiwedzera kunyaradzwa kwemushandisi uye ergonomics. Kuchinjika kwayo kwakanyanya kunobvumira kugadzirwa kwemaumbirwo akaomarara uye magadzirirwo, zvichibvumira vagadziri kuburitsa hunyanzvi hwavo.

Kunamatira Kunoshamisa: Si-TPV inoratidza kunamira kwakanaka kune substrates dzenylon, zvichiita kuti igare yakasimba uye yakasimba muzvikamu zvakaumbwa zvakanyanya. Izvi zvinobvisa njodzi yekuparadzaniswa kana kupatsanurwa, kunyangwe mukushandiswa kwakaoma.

Kugara Kwakasimba: Si-TPV inopa simba rakanaka pakusakara, kubvaruka, uye zvinhu zvakatipoteredza, zvichiita kuti ishande kwenguva refu uye yakavimbika mumamiriro ezvinhu akaoma.

Kuchinja-chinja: Si-TPV inoenderana nemhando dzakasiyana dzemhando dzenylon uye matekiniki ekugadzirisa, zvichiita kuti ive yakakodzera kushandiswa kwakasiyana-siyana kwe overmolding mumaindasitiri akasiyana-siyana.

Inoyevedza: Si-TPV inowedzera kutaridzika kwezvikamu zvakaumbwa zvakanyanya nekupenya kwayo kwakapfava uye mavara akajeka. Kugona kwayo kuchengetedza magadzirirwo neruzivo kunowedzera runako rwechigadzirwa chekupedzisira.

Mashandisirwo eSi-TPV muNylon Overmolding:

Si-TPV inowana mashandisirwo mumaindasitiri akasiyana-siyana, anosanganisira mota, zvemagetsi, zvinhu zvevatengi, zvishandiso zvekurapa, nezvimwewo. Mamwe mashandisirwo akajairika anosanganisira:

Zvikamu zvemukati memotokari zvakaita senzvimbo dzinobata zvinyoro-nyoro, nzvimbo dzekuzororera maoko, uye mibato

Zvishongedzo zvemagetsi zvevatengi zvakaita semakesi efoni, mavhavha emahedhifoni, uye maremote controls

Zvikamu zvemidziyo yekurapa zvinoda zvinhu zvakapfava uye zvinoenderana nehupenyu

Zvishandiso zvemitambo nemidziyo ine zvinobata zvakanaka uye zvinodzivirira

Mhedziso:Si-TPV inovhura mikana mitsva kune vagadziri nevagadziri vari kutsvaga kugadzira zvigadzirwa zvitsva uye zvemhando yepamusoro zvakaumbwa. Kunyangwe uri kutsvaga kusimudzira kugadzikana kwevashandisi, kuvandudza runako rwezvigadzirwa, kugadzirisa matambudziko ekunamatira, kugadzirisa kupwanyika uye kuderera, kana kugadzirisa maitiro ekugadzira, Si-TPV ndiyo sarudzo yakakodzera zvinodiwa zvako zvekuumbwa kwenylon.

Usarega Matambudziko Achikudzivisa! Gamuchira simba reSi-TPV uye vhura mikana mitsva yekubudirira mukugadzira nylon overmolding. Bata SILIKE izvozvi kuti udzidze zvakawanda nezvekusimudzira maitiro ako ekugadzira nylon overmolding kusvika padanho idzva rekushanda uye kushanda zvakanaka.

Nhare: +86-28-83625089 kana +86-15108280799

Email: amy.wang@silike.cn

Webhusaiti: www.si-tpv.com