Tsanangudzo

Iyo SILIKE Si-TPV 2150 Series imhando ye elastomer ine vulcanizate silicone-based, yakagadzirwa uchishandisa tekinoroji yepamusoro yekubatana. Maitiro aya anoparadzira rabha re silicone muSEBS sezvidimbu zvidiki, kubva pa1 kusvika ku3 microns pasi pe microscope. Izvi zvinhu zvakasiyana zvinosanganisa simba, kuomarara, uye kuramba kukwesha kwe thermoplastic elastomers nezvinhu zvinodiwa zve silicone, zvakaita sekupfava, kunzwa kwesilika, uye kuramba chiedza cheUV nemakemikari. Pamusoro pezvo, zvinhu zveSi-TPV zvinogona kudzokororwa uye zvinogona kushandiswazve mumaitiro ekugadzira echinyakare.

Si-TPV inogona kushandiswa zvakananga sezvinhu zvisina kugadzirwa, yakagadzirirwa kushandiswa muzvinhu zvemagetsi zvinopfekwa, mabhokisi ekudzivirira emidziyo yemagetsi, zvikamu zvemotokari, maTPE emhando yepamusoro, uye maindasitiri ewaya eTPE.

Kupfuura kushandiswa kwayo zvakananga, Si-TPV inogonawo kushanda sepolymer modifier uye process additive ye thermoplastic elastomers kana mamwe ma polymer. Inowedzera elasticity, inovandudza processing, uye inowedzera hunhu hwepamusoro. Kana ikasanganiswa ne TPE kana TPU, Si-TPV inopa kupfava kwepamusoro kwenguva refu uye kunzwa kunonakidza kwekubatwa, ukuwo ichivandudzawo kuramba kukwenya nekukwenya. Inoderedza kuomarara pasina kukanganisa hunhu hwemuchina uye inopa kukwegura kuri nani, yero, uye kuramba mavara. Inogona zvakare kugadzira matte finish inodiwa pamusoro.

Kusiyana nezvinowedzera zvesilicone zvechinyakare, Si-TPV inowanikwa muchimiro chepellet uye inogadziriswa sethermoplastic. Inopararira zvakanaka uye zvakaenzana mukati mepolymer matrix, uye copolymer inobatanidzwa mumuviri kune matrix. Izvi zvinobvisa kunetseka kwekufamba kana matambudziko "anotumbuka", zvichiita kuti Si-TPV ive mhinduro inoshanda uye itsva yekuwana nzvimbo dzakapfava dzesilky mu thermoplastic elastomers kana mamwe mapolymer. uye haidi mamwe matanho ekugadzirisa kana ekupenda.

Mabhenefiti Akakosha

- MuTPE

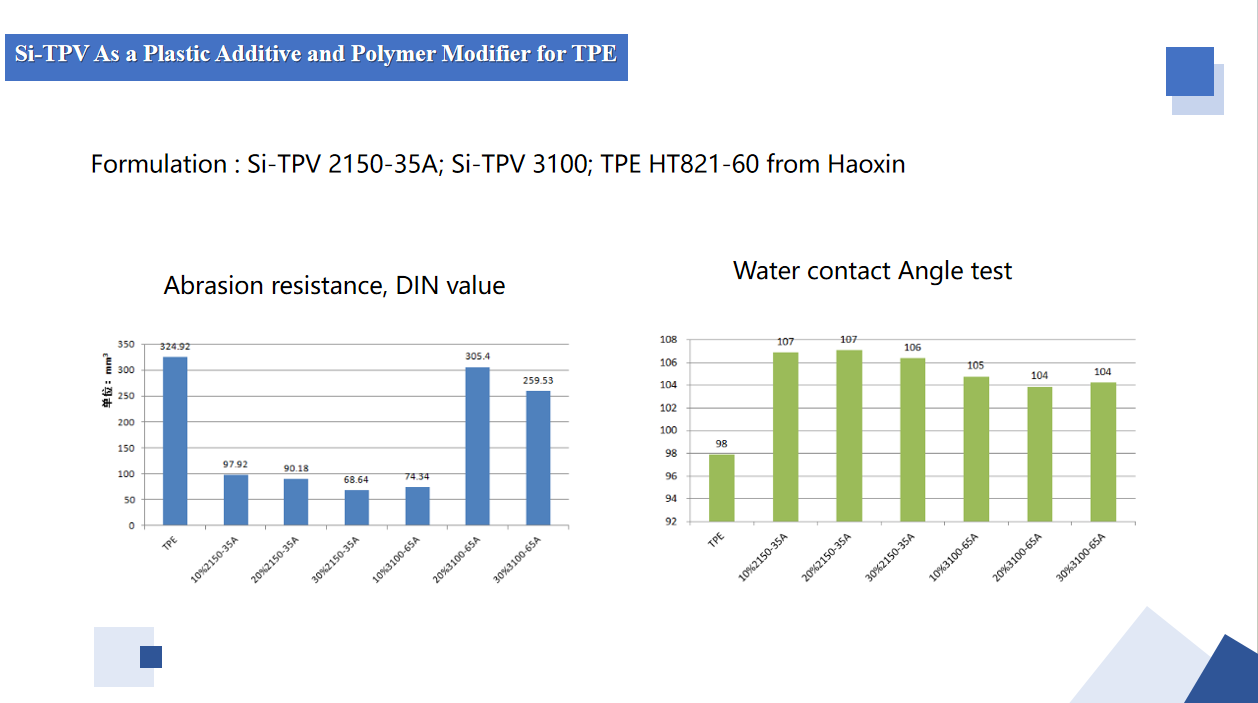

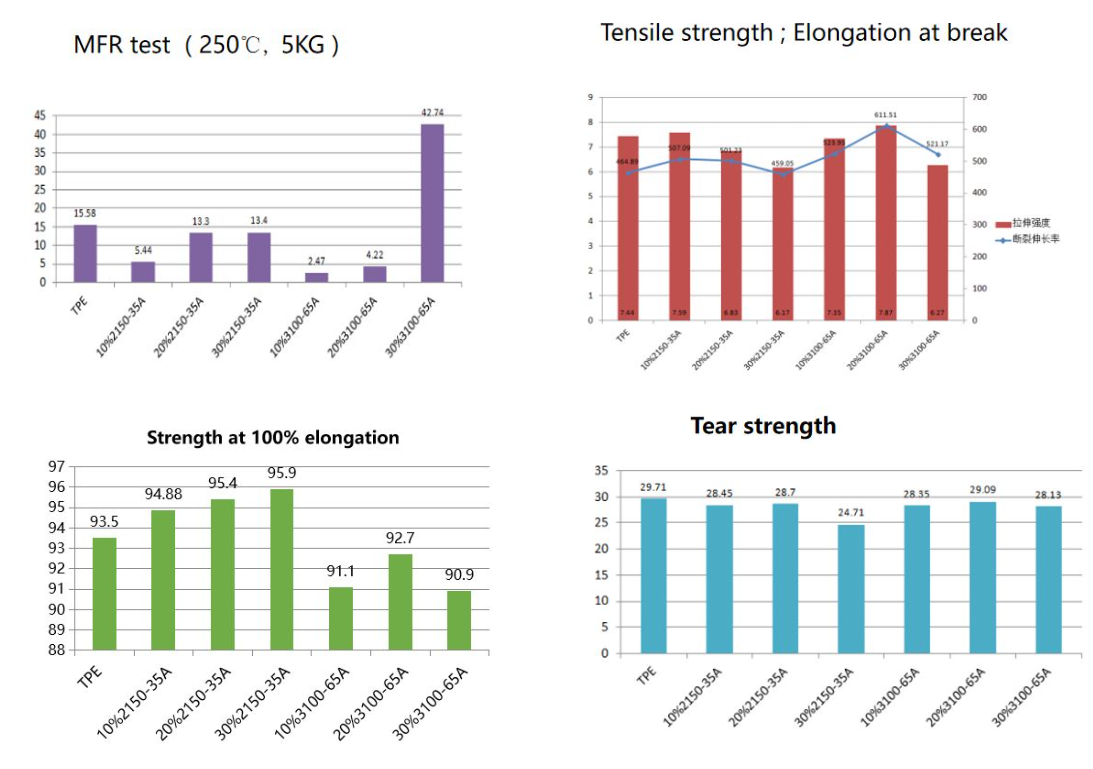

- 1. Kuramba kweAbrasion

- 2. Kudzivirira mavara nekona diki yekubata mvura

- 3. Deredza kuomarara

- 4. Hapana kana simba pahunhu hwemakanika neSi-TPV 2150 series yedu

- 5. Magadzirirwo akanaka kwazvo, kubata kwakaoma kwesilika, hapana kutumbuka mushure mekushandiswa kwenguva refu

Kugara kwenguva refu Kugara kwenguva refu

- Tekinoroji yepamusoro isina zvinonyungudutsa, isina plasticizer, isina mafuta anonyorovesa, uye isina hwema.

- Kudzivirirwa kwezvakatipoteredza uye kugona kudzokororwa.

- Inowanikwa mumafomura anotevedzera mitemo.

Zvidzidzo zveSi-TPV zvepurasitiki zvinowedzerwa uye zvinogadzirisa polymer

Si-TPV 2150 series ine hunhu hwekubata ganda zvinyoro nyoro kwenguva refu, inodzivirira mavara zvakanaka, haina plasticizer uye softener yakaiswa, uye haina mvura mushure mekushandiswa kwenguva refu, iyo inoshanda sepurasitiki uye polymer modifier, inonyanya kushandiswa pakugadzirira silky pleasant feel thermoplastic elastomers.

Kuenzanisa Mhedzisiro yeSi-TPV Plastic Additive nePolymer Modifier pakushanda kweTPE

Kushandiswa

Si-TPV inoshanda senzira itsva yekugadzirisa manzwiro uye yekuwedzera mashandiro e thermoplastic elastomers nedzimwe polymers. Inogona kusanganiswa ne elastomers dzakasiyana-siyana uye mainjiniya kana mapurasitiki akajairika, akadai seTPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, uye PVC. Mhinduro idzi dzinobatsira kusimudzira mashandiro ekugadzirisa uye kuvandudza mashandiro ekudzivirira kukwenya nekukwenya kwezvikamu zvakapedzwa.

Chinhu chikuru chinowanikwa muzvigadzirwa zvakagadzirwa neTPE neSi-TPV blends kugadzira silk-soft surface isingabatike—izvo chaizvo zvinotarisirwa nevashandisi kubva pazvinhu zvavanobata kana kupfeka. Chinhu ichi chinoshamisa chinowedzera huwandu hwezvinogona kushandiswa muzvinhu zveTPE elastomer mumaindasitiri akasiyana-siyana. Uyezve, kushandisa Si-TPV semugadziri wezvinhu kunowedzera kuchinjika, kusimba, uye kugara kwenguva refu kwezvinhu zve elastomer, ukuwo zvichiita kuti maitiro ekugadzira ave akaderera.

Mhinduro:

Uri Kunetseka Nekusimudzira Kushanda kweTPE Here? Zvimwe zveSi-TPV Plastic uye polymer modifiers Zvinopa Mhinduro

Nhanganyaya kuTPEs

Ma elastomer eThermoplastic (TPEs) anorongwa zvichienderana nemakemikari, anosanganisira Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), uye Copolyamides (COPA). Kunyange zvazvo ma polyurethanes nema copolyesters angave akagadziriswa zvakanyanya kuti ashandiswe, sarudzo dzinodhura zvakanyanya dzakadai seTPE-S neTPE-V dzinowanzo kupa kukodzera kuri nani kwekushandisa.

MaTPE echinyakare anosanganiswa nerabha nethermoplastics, asi maTPE-Vs akasiyana nekuti ane zvidimbu zverabha zvakabatana zvishoma kana zvizere, zvichivandudza mashandiro azvo. MaTPE-Vs ane ma "compression sets" akaderera, anodzivirira makemikari nekukwesha zviri nani, uye kugadzikana kwakanyanya pakupisa, zvichiita kuti akwanise kutsiva rabha mu "seals". Kusiyana neizvi, maTPE echinyakare anopa kuchinjika kukuru kwekugadzirwa, simba rakawanda rekudhonza, kuchinjika, uye ruvara, zvichiita kuti akwanise zvigadzirwa zvakaita sezvinhu zvevatengi, zvemagetsi, uye zvekurapa. Anobatanidzwawo zvakanaka kune zvinhu zvakasimba zvakaita sePC, ABS, HIPS, uye Nylon, izvo zvinobatsira pakushandisa zvinyoro-nyoro.

Matambudziko neTPE

MaTPE anosanganisa kusimba kwemuviri nesimba remuchina uye kugona kwawo kugadzikisa zvinhu, zvichiita kuti akwanise kushandiswa zvakasiyana-siyana. Hunhu hwawo hwekusimba, hwakadai sekumanikidzwa uye kureba, hunobva muchikamu che elastomer, nepo simba rekusimba uye kubvaruka zvichienderana nechikamu chepurasitiki.

MaTPE anogona kugadziriswa semathermoplastics echinyakare pakupisa kwakanyanya, kwaanopinda muchikamu chekunyunguduka, zvichibvumira kugadzirwa kwakanaka uchishandisa michina yepurasitiki yakajairwa. Kupisa kwavo kwekushanda kunoonekwawo, kubva pakupisa kwakaderera zvikuru—pedyo nenzvimbo yekuchinja kwegirazi yechikamu che elastomer—kusvika pakupisa kwakanyanya kuri pedyo nenzvimbo yekunyunguduka yechikamu che thermoplastic—zvichiwedzera kushanduka kwavo.

Zvisinei, pasinei nemabhenefiti aya, matambudziko akati wandei achiripo mukuvandudza mashandiro eTPE. Dambudziko guru nderekuoma kwekuenzanisa kusimba kwemuchina. Kuvandudza chimwe chinhu kunowanzoita kuti chimwe chive chinodhura, zvichiita kuti zviomere vagadziri kugadzira maTPE anochengetedza kuenzana kwakaringana kwezvinhu zvinodiwa. Pamusoro pezvo, TPE dzinogona kukuvara pamusoro senge kukwenya uye kupwanya, izvo zvinogona kukanganisa chitarisiko uye mashandiro ezvigadzirwa zvakagadzirwa nezvinhu izvi.